Add to Cart

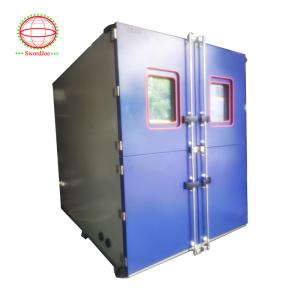

Two Zone Thermal Shock Test Chamber Apply In Aerospace, Automotive, Electronics, And Military Applications

Thermal Shock Test Chamber is a specialized environmental testing equipment used to evaluate the durability and reliability of products and components when subjected to rapid and extreme temperature changes. It simulates real-world conditions where devices might experience sudden temperature fluctuations, such as in aerospace, automotive, electronics, and military applications.

Thermal Shock Test Chamber:

The Thermal Shock Test Chamber is designed to quickly alternate products between high and low temperatures, creating a thermal stress that helps identify potential failures or weaknesses in materials and assemblies. The chamber typically consists of two or more temperature-controlled sections, often with a transfer mechanism that moves the test sample between the hot and cold zones. This rapid cycling ensures that the product is exposed to abrupt temperature variations, mimicking harsh environmental conditions.

Key Features:

Applications:

In Summary:

A Thermal Shock Test Chamber is an essential tool for simulating the extreme temperature variations that products may encounter in real-world scenarios, thereby helping manufacturers improve product robustness and ensure compliance with quality standards.

| Model | JQTS2-50 | JQTS2-80 | JQTS2-100 | JQTS2-150 | JQTS2-225 | JQTS2-408 |

| Inner size | 35*32*40 | 50*40*40 | 50*50*40 | 65*50*46 | 65*70*50 | 85*80*60 |

| Outer size | 125*160*185 | 135*170*185 | 140*185*190 | 160*190*205 | 160*230*210 | 180*250*230 |

| Capacityt(L) | 50L | 80L | 100L | 150L | 225L | 408L |

| Weight(kg) N.W | 800 | 900 | 950 | 1050 | 1250 | 1450 |

| Temp.Shock Range | A:-40℃~180℃ B:-55℃~180℃ C:-65℃~180℃ | |||||

| Shock type | 1. High Temp.→Low Temp. 3. Normal Temp →High Temp. →Normal Temp. →Low Temp. | |||||

| High Temp. Chamber | +60°C~+200°C | |||||

| Pre-Heating Time | (+20°C~200℃) <35 minutes | |||||

| Low Temp.Chamber | (-40°C/-55°C/-65°C) ~ -10°C | |||||

| Pre-cooling Time | (+20°C~-75℃ )< 60minutes | |||||

| Temperature | ‘-40℃/-55°C/-65℃~+180℃ <5 second (Two Zone) | |||||

| Recover time | Heat chamber Exposure 30min | |||||

| Cold chamber Exposure 30 min | ||||||

| within 5~10min | ||||||

| Temp.fluctuation range | ±0.5℃ | |||||

| Chamber material | Outer shell : standard 1.5mm electrolytic plate Baked electrostatic painting | |||||

| Insulation material |

| |||||

| Controller | 7'LCD colorful Chinese and English touch screen (10 inch optional ),Program or fix setting ,120sets programs ,1200steps USB ,RS232 /R485 interface ,mobile APP , computer connection remote control (optional network interface ) | |||||

| Control system | P.I.D+S.S.R+Temp control system of microcomputer balance | |||||

| Cooling type | Semi-closed two-stage compressor (water cooled) | |||||

| Refrigant | HFC-404a and HFC23 /HFC-R449A/HFC-507 | |||||

| Compressor | Fully closed French “Tecumseh “compressor | |||||

| Safety protection device | Fuse free switch, compressor high and low voltage protection switch,Over-temperature potector,Over -current protector , Refrigerant high -voltage protection switch, fault alarm system, electronic sound light alarm device | |||||

| Spare parts | Glass viewing window , two shelves , 2*¢50mm cable Ports ,Casters , | |||||

| Power Supply | AC/380V,50HZ,20~50A, | |||||